- HOME

- Facilities and equipment

Facilities and equipment

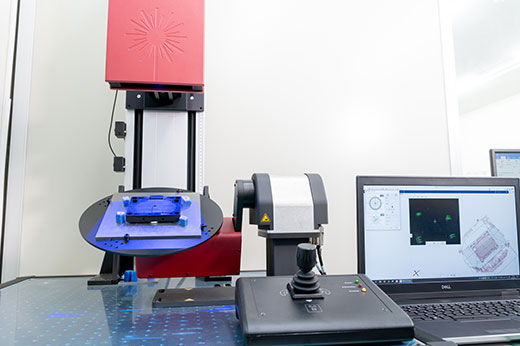

At Sanko Kasei, we are committed to partnering closely with clients at every step of the manufacturing journey. All our production facilities boast the latest equipment and systems for producing precision plastic components to the highest standards of quality. Equipment is transferred between production facilities in Japan to maximize speed and flexibility of production scheduling so that we can meet client requirements and provide comprehensive support.

Key equipment

-

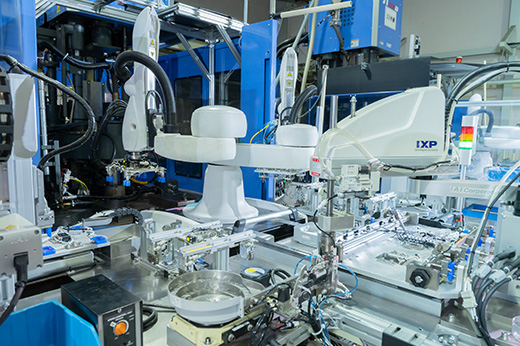

Automatic insert processor (Ichinoseki and Hanaizumi)

-

Automatic insert dual arm robot (Hanaizumi)

-

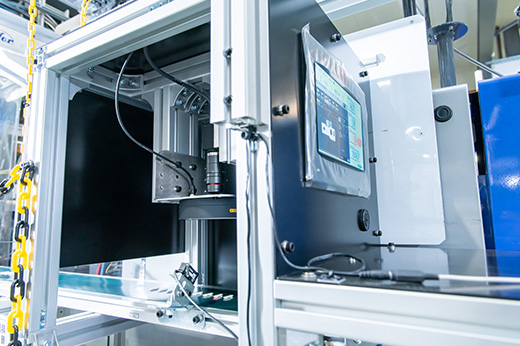

Imaging inspection system/Imaging inspection line (Fukushima, Ichinoseki and Hirosaki)

-

Child protection seat for washroom assembly line (Fukushima)

-

Auto stocker (Fukushima)

-

Short-circuit detector at discharge point with camera (Fukushima)

-

Automated measurement data input system (Tajimi)

-

Automated damper assembly machine (Hiroshima)

-

Automated ultrasonic welding line (Hiroshima)

-

Drying timer with secondary feed interlock to dryer (Hiroshima)

-

Molding machine coolant failure warning system (Hiroshima)

-

Waterless system automatic switching supply (Hiroshima)

-

Toyota Production System (Ichinoseki No. 2)

-

Vibration welder (Ichinoseki No. 2)

-

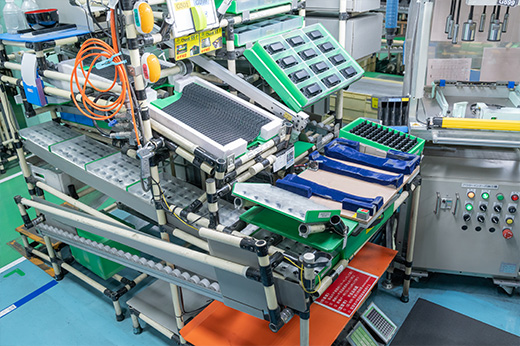

Blended robot-operator production line (Ichinoseki No. 2)

-

Karakuri machine (Ichinoseki No. 2 and Hanaizumi)

-

Pre-assembly component checking system (Ichinoseki No. 2)

-

Automated welding and inspection line (Miyagi)

-

Clean room welding center (Miyagi)

-

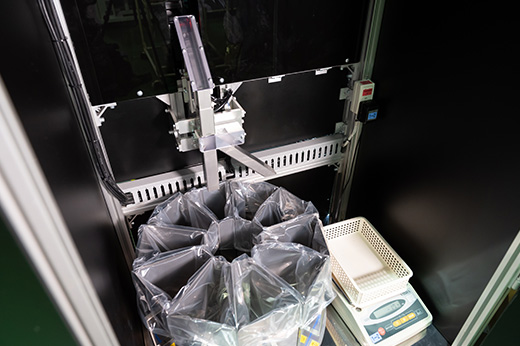

Automated packaging line (Hirosaki)

-

Automatic composite molding line (assembly plus insert molding) (Hirosaki)

-

Automated recycling/molding line (Hirosaki)

-

3D scanner (Asaka and Mold Factory)