- HOME

- Measurement and Evaluation

Quality guaranteed under our internationally certified quality control system

Sanko Kasei employs a preventative quality control strategy to ensure ongoing uniformity and consistency of quality standards, using logging data to monitor work pieces and automatically reject any that deviate from threshold requirements.

More recently, optimization of threshold requirements has been used to drive further quality enhancements.

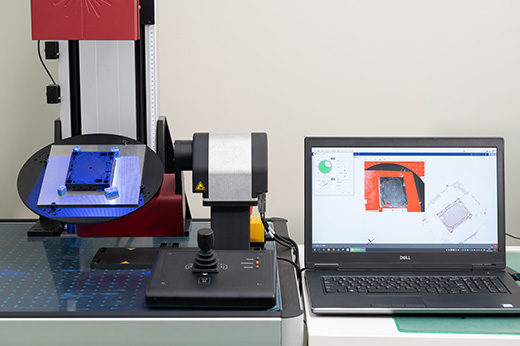

Quality control is predicated on high-precision testing and evaluation at the pre-production stage. Sanko Kasei is committed to boosting technical standards through process specialization and is actively pursuing automation solutions such as automated digital imaging inspection systems as part of our comprehensive quality assurance regime.

At Sanko Kasei, it is technology that underpins our outstanding technical performance and manufacturing capacity which in turn serve as the foundation for industry-leading quality standards.

As proof of our unwavering commitment to quality standards, Sanko Kasei was awarded ISO 9001 international certification at an early stage. We have invested heavily in testing and evaluation systems to ensure consistency and uniformity of quality standards in line with client expectations across a range of industries.

-

Inspection room

-

3D measuring system

-

Automated digital imaging inspection system

-

Microscopic inspection device

-

3D scanner