- HOME

- Production control and shipping

Sanko Kasei works closely with clients on production and shipping schedules.

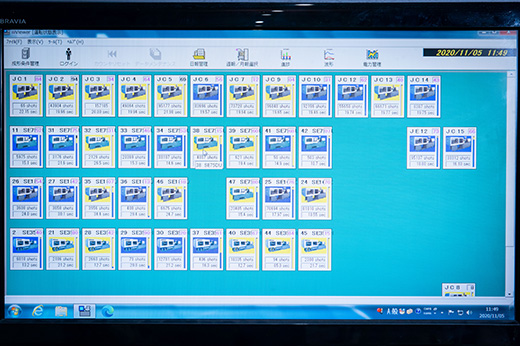

Sanko Kasei is committed to working closely with clients at all stages of the manufacturing journey. With a powerful, rapid-response production management system combined with an advanced server-client network system, Sanko Kasei endeavors to accommodate client requirements with respect to Production control and shipping.

Sanko Kasei produces plastic molded products for use in a wide range of fields, from precision machinery components to exterior trim, office equipment, digital devices, electronic and electric components, IT, automotive and onboard equipment, medical supplies, bathroom products, cosmetics, security systems, railways and construction. Our modern production systems can accommodate a range of Production control and shipping requests. Contact us to find out more.

Automated packaging line

The automated packaging line is a high-efficiency system for packaging up finished products for shipment.

Shorter delivery period

Efficient data processing and data sharing is a key aspect of Production control and shipping.

At Sanko Kasei, we use the Kanban system for production and delivery scheduling together with an hour-by-hour vehicle tracking system to ensure timely deliveries.

The Sanko Kasei group is committed to continuous improvement in delivery times using our impressive global network. Client requests are immediately broadcast to the network, and a coordinated response is immediately formulated for presentation to the client, with a strong focus on not just speed but on meeting the client’s expectations. It is the Sanko Kasei network that makes this possible.